Advances in nanotechnology have made ceramic coatings the hottest category in the world of automotive detailing. There are a lot of marketing claims being made by manufacturers of ceramic coatings and consumers should do their research, ask a lot of questions, and proceed cautiously.

Quality ceramic coatings leave a very slick finish making it difficult for dirt, dust and debris to stick to the clear coat. If you use proper washing techniques these particles will be easily removed with much less chance of creating fine scratches and swirls in your paint. Automated car washes will create swirl marks and hand washing with a wash mitt that is not carefully cleaned will create swirl marks on a coated vehicle.

Coatings do offer a lot of advantages for people that don’t want to regularly wash, polish and apply sealants or waxes to their vehicle. Today’s high-solids, resin-based coatings are better than ever and they provide a long lasting glossy appearance that I describe as looking like wet rock candy. Coatings provide excellent protection from low and high temperatures and they protect the top layer of clear coat from both acid and alkaline chemicals. Northern Nevada’s climate is tough on vehicles that spend a lot of time outside. Ceramic Coatings offer the best protection against damage from ultraviolet rays and the resulting oxidation that can fade and dull your paint.

In short, coatings do have a lot to offer but they are not the best solution for every type of owner. Ceramic coatings will not stop pitting and dings from small pebbles and rock debris that strike your car. Paint Protection Film is the only product that is effective against this kind of damage.

If you’re looking for a product that will reduce the amount of time you spend trying to keep your car clean and shiny then a ceramic coating is probably the best choice. It’s important to have a paint correction done before applying any coating. Otherwise, you’re just sealing in the scratches and swirls and you won’t enjoy the highly reflective gloss that only comes from a professionally polished painted surface. It’s the paint surface that reflects the light that creates a brilliant shine.

For those who want to learn more about ceramic coatings, I will now go into more detail about the chemistry of coatings.

New Update – January 2025

Automotive coatings are improving every year and new formulas become available as manufacturers compete for sales. I constantly test new coatings that promise greater longevity and more resistance to chemicals and hard water spots. Water spots are the most common problem with many coatings.

A new supplier, C6 CERAMICS, has developed a breakthrough in ceramic coating chemistry. This formula contains four primary components that are blended together using heat and pressure. These components are:

- Silicon Dioxide (Si02) : Creates hardness and gloss. This ingredient is found in most ceramic coatings.

- Silicon Carbide (SiC) : Provides high resistance to chemicals from pH-2 to pH-13. Silicon Carbide also provides high gloss.

- Silicon Nitride (Si3N4) : A high-performance ceramic material with very high fracture toughness. This structural ceramic has great flexing strength which increases the bond between the coating and the paint on your car.

- Refined Detonated Nano Diamonds: Nano-diamonds are created in a lab by exploding a piece of carbon inside a heavy metal sphere. The nano-diamonds are harvested from the inside of the sphere and then milled so that each diamond particle is exactly the same size. When the nano-diamonds are blended with the other ingredients the coating becomes super resistant to fracturing and water spots. The result is the best performing coating I have ever used as of January 2025.

What Causes A Ceramic Coating to Wear Out or Fail?

A ceramic coating does not wear off the paint but over time it loses its protective and hydrophobic (water beading) properties. The thickness of a ceramic coating does not mean it will provide better protection. Longevity is determined by resistance to fracturing. Fracturing occurs because the paint on your car expands and contracts every day. Heat from the engine and the sun expands the micro pores of the coating and then at night cold air shrinks the pores. These daily hot & cold cycles cause coatings to fracture and develop microscopic fissures. You will notice water does not bead up and slide off the paint as fast as when the coating was new. Dirt and dust will stick to the paint and your car will need more frequent washing. In northern Nevada our daily temperature fluctuates more than most other locations because of the high desert climate and altitude. This is the reason many ceramic coatings don’t last as long as they should. Refined Detonated Nano Diamonds and Silicon Nitride prevent fracturing and micro cracking and enable C6 CERAMICS coatings to outlast all the other products I have used and tested the past seven years.

In the picture above you can see the structure of Graphene appears as a honeycomb latticework of carbon atoms.

True graphene is stronger than steel and harder than diamonds. In fact, graphene is the strongest, stiffest material known to scientists. It is so thin it’s hard to conceptualize!

A sheet of graphene is invisible to the human eye and it’s so strong it basically impenetrable. These qualities are driving chemists to incorporate Graphene Oxide into ceramic coatings.

Several coating manufacturers use reduced Graphene Oxide to improve resistance to water spots. My long-term testing confirms that reduced

Graphene Oxide reduces water spots. In my opinion, ARTDESHINE makes ceramic coatings that are among the most resistant to water spots.

I am a “Certified Installer” for ARTDESHINE and I apply their top of the line Nano Graphene Coating for clients that are concerned about water spots. Watch this YouTube video from Dmitry’s Garage where he tests the Artdeshine Nano Graphene Coating NGC+.

(Dmitry’s Garage is a YouTube channel that does unbiased, scientific testing of auto detailing products. This is the link https://youtu.be/FolPaKwZk8o?si=f-FONufo8KuVE54s

The Role Curing Plays In the Longevity of Ceramic Coatings

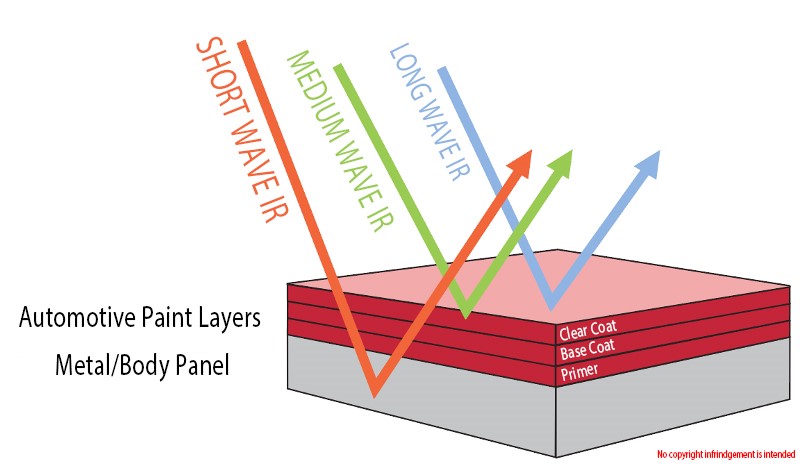

Short Wave infrared paint curing lights are the best available equipment for curing (drying) automotive paints and coatings. Unlike older medium wave infrared lights, which were used on flat surfaces, short wave infrared can be used on all convex and concave exterior panels of a vehicle. The short wave infrared heating tubes radiate energy that passes through the Clear Coat, Base Coat and Primer to heat the steel or aluminum body panels. The heated metal radiates the heat back through the paint and into the coating so it cures evenly from the inside out. This creates a strong bond between the high-solids ceramic coating and the Clear Coat on your vehicle. This is illustrated in the diagram below.

Additionally, infrared curing allows the solvents in the coating to be pushed out to the surface in a controlled and consistent manner. Most detailing shops don’t have this equipment and the vehicle is allowed to simply air dry. A full cure will take up to ten days when a vehicle is air dried, depending on temperature and humidity. This year I purchased a new industrial short wave infrared curing fixture that is equipped with an ultrasonic distance sensor and precision temperature sensor. This equipment monitors the temperature of the heated body panel every second during the baking process and precisely controls the curing temperature resulting in a curing process that allows the ceramic coating to achieve maximum hardness and bonding with the Clear Coat in about 15-minutes. This also works beautifully when coating wheels, glass and plastic trim.

If you want a quality installation of a high-solids ceramic coating its no different than having your car repaired and repainted at an autobody shop. You would not be happy if the repaired area was just sprayed with fresh paint and allowed to air dry. That is why autobody shops use paint booths and shortwave infrared light to control the application and curing of the paint and deliver a long lasting repair that will protect the value of your automobile.

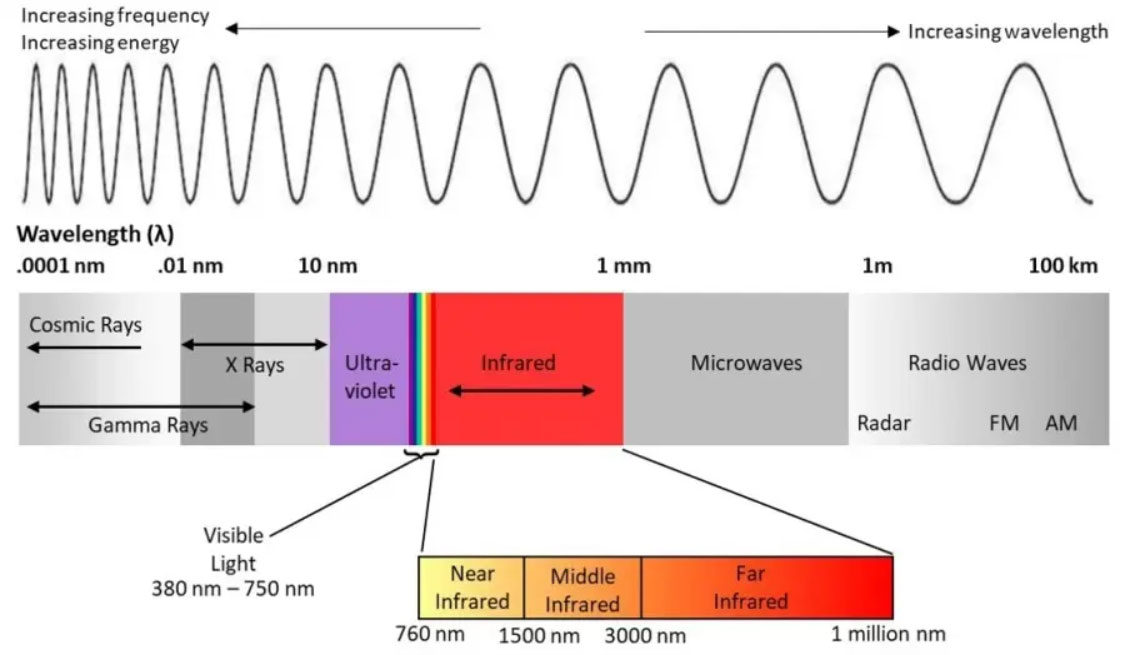

Infrared is part of the electromagnetic spectrum. As you move to the left side of the spectrum the electromagnetic waves become shorter (waves are closer together). The energy and frequency of shortwave infrared (also known as Near Infrared) is more powerful than medium- wave infrared (also known as Middle Infrared). This increased energy speeds up the movement of molecules, creating heat, and this accelerates the curing process. To help visualize these concepts take a look at the electromagnetic spectrum in the diagram below.

One last factor to consider is coating maintenance. A professional, high-solids ceramic coating must be properly cleaned and treated with a maintenance spray that is designed to be used with the underlying coating. Maintenance should be done about three times per year to renew the top layer and restore the slickness and hydrophobic effects of the coating so it will continue to perform for several years.

To summarize, there are lots of things to consider before deciding where you want to have a ceramic coating installed. Call me and describe how you use your vehicle and I can recommend the best coating product for you.